超高溫閥門」是指適用于介質(zhì)溫度大于600℃以上的閥門����。

Ultra high temperature valve "refers to a valve suitable for medium temperatures above 600 ℃.

01閥門組成

01 Valve composition

1.核心部件

1. Core components

一個具有圓形通道的球體�,由耐高溫�、耐腐蝕的材料制成。球體中間開有一個通孔���,通過旋轉(zhuǎn)球體來實現(xiàn)閥門的開啟與關(guān)閉�。

A sphere with circular channels, made of materials that are resistant to high temperatures and corrosion. There is a through-hole in the middle of the sphere, and the valve can be opened and closed by rotating the sphere.

2.氣動執(zhí)行器

2. Pneumatic actuator

負責接收控制信號并轉(zhuǎn)換為機械動力�,驅(qū)動球體旋轉(zhuǎn)。常見的有直行程和角行程兩種類型�����。

Responsible for receiving control signals and converting them into mechanical power to drive the rotation of the sphere. There are two common types: straight stroke and angular stroke.

3.其他部件

3. Other components

包括閥體、密封結(jié)構(gòu)��、排放與防火設計等����。閥體通常采用高質(zhì)量鑄鋼或不銹鋼材料,以承受高溫和壓力���;密封結(jié)構(gòu)采用硬密封設計��;閥門還設計有排泄孔�����,可以在關(guān)閉過程中排出腔體內(nèi)殘留的介質(zhì)�����,防止超壓�。

Including valve body, sealing structure, discharge and fire protection design, etc. Valve bodies are usually made of high-quality cast steel or stainless steel materials to withstand high temperatures and pressures; The sealing structure adopts a hard sealing design; The valve is also designed with a discharge hole, which can discharge the residual medium in the chamber during the closing process to prevent overpressure.

02工作原理

02 Working principle

當氣動執(zhí)行機構(gòu)接收到控制信號后���,壓縮空氣驅(qū)動活塞或薄膜運動�����,進而通過一系列機械傳動裝置使球體旋轉(zhuǎn)90度�。

When the pneumatic actuator receives a control signal, compressed air drives the piston or diaphragm to move, and then rotates the sphere 90 degrees through a series of mechanical transmission devices.

當球體上的通孔與閥門兩端的管道對準時,閥門開啟��,流體可以通過�����;當球體旋轉(zhuǎn)90度使得通孔與管道垂直時�����,閥門關(guān)閉���,有效阻止流體流動�����。通過配置閥門定位器,還可以實現(xiàn)對閥門的精確控制�����,根據(jù)控制信號大小相應控制閥門的開度,從而實現(xiàn)對介質(zhì)流量����、壓力、溫度等參數(shù)的精確調(diào)節(jié)�����。

When the through-hole on the sphere is aligned with the pipes at both ends of the valve, the valve opens and fluid can pass through; When the sphere rotates 90 degrees so that the through-hole is perpendicular to the pipeline, the valve closes, effectively preventing fluid flow. By configuring a valve positioner, precise control of the valve can also be achieved. The valve opening can be controlled according to the size of the control signal, thereby achieving precise adjustment of parameters such as medium flow rate, pressure, and temperature.

03性能特點

03 Performance Characteristics

1.耐高溫高壓

1. High temperature and high pressure resistance

采用耐高溫合金材料制成��,能夠承受閥門在高溫高壓環(huán)境下工作條件���,確保閥門在高溫高壓下依然能夠穩(wěn)定運行���。

Made of high-temperature resistant alloy materials, it can withstand the working conditions of valves in high temperature and high pressure environments, ensuring that valves can still operate stably under high temperature and high pressure.

2.結(jié)構(gòu)緊湊

2. Compact structure

整體設計緊湊,體積小巧�,便于安裝和維護。

The overall design is compact, with a small volume that is easy to install and maintain.

3.適應性強

3. Strong adaptability

針對多樣化的需求��,提供多種規(guī)格和定制化解決方案�,確保在不同工況下都能穩(wěn)定運行。

We provide a variety of specifications and customized solutions to meet diverse needs, ensuring stable operation under different working conditions.

4.密封性好

4. Good sealing performance

采用金屬硬密封閥座��,密封性能可靠�,適用于介質(zhì)是粘稠�����、含顆粒���、纖維性質(zhì)的場合。

Adopting a metal hard sealed valve seat, the sealing performance is reliable and suitable for occasions where the medium is viscous, contains particles, or has fiber properties.

5.操作方便

5. Easy to operate

開閉迅速����,從全開到全關(guān)只需旋轉(zhuǎn)90°,便于遠距離的控制���。

Quick opening and closing, only need to rotate 90 ° from fully open to fully closed, making it easy to control from a distance.

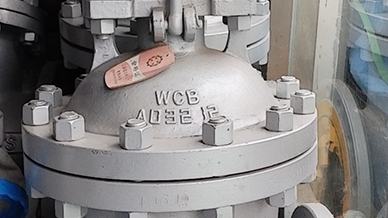

圖片

Picture

04應用領(lǐng)域

04 Application Fields

氣動高溫球閥因其高效���、可靠、易于遠程控制等特點���,在多個領(lǐng)域得到廣泛應用�,包括但不限于:

Pneumatic high-temperature ball valves are widely used in various fields due to their high efficiency, reliability, and ease of remote control, including but not limited to:

2.石油

2. Oil

用于管道輸送系統(tǒng)和化工生產(chǎn)裝置中����,控制高溫高壓油氣的流動����。

Used in pipeline transportation systems and chemical production facilities to control the flow of high-temperature and high-pressure oil and gas.

3.化工

3. Chemical industry

控制高溫腐蝕性介質(zhì)的輸送����,防止介質(zhì)泄漏和環(huán)境污染�����。

Control the transportation of high-temperature corrosive media to prevent media leakage and environmental pollution.

4.教學設備

4. Teaching equipment

在實驗室或教學設備中�����,用于模擬或控制高溫流體的流動��。

Used in laboratories or teaching equipment to simulate or control the flow of high-temperature fluids.

5.輕工

5. Light Industry

在輕工行業(yè)中��,用于高溫介質(zhì)的輸送和控制��。

In the light industry, it is used for the transportation and control of high-temperature media.

6.高壓設備

6. High voltage equipment

如鍋爐����、蒸汽發(fā)生器等高壓設備中,控制高溫高壓蒸汽的流動��。

Control the flow of high-temperature and high-pressure steam in high-pressure equipment such as boilers and steam generators.

7.制藥

7. Pharmaceutical

用于藥品生產(chǎn)設備和潔凈系統(tǒng)中,確保介質(zhì)的潔凈度和生產(chǎn)線的安全穩(wěn)定��。

Used in pharmaceutical production equipment and clean systems to ensure the cleanliness of the medium and the safety and stability of the production line.

8.造紙

8. Paper making

在造紙行業(yè)中�����,控制高溫介質(zhì)的輸送��,如蒸汽����、熱水等。

In the papermaking industry, controlling the transportation of high-temperature media such as steam, hot water, etc.

9.新能源

9. New energy

如太陽能光熱發(fā)電站��、地熱發(fā)電系統(tǒng)�����、生物質(zhì)燃料轉(zhuǎn)化裝置等���,控制高溫流體的流動�。

Such as solar thermal power plants, geothermal power generation systems, biomass fuel conversion devices, etc., control the flow of high-temperature fluids.

05維護與保養(yǎng)

05 Maintenance and upkeep

為確保氣動高溫球閥的正常運行和延長使用壽命�����,應定期進行維護與保養(yǎng):

To ensure the normal operation and extend the service life of pneumatic high-temperature ball valves, regular maintenance and upkeep should be carried out:

定期檢查

Regular inspection

檢查閥門的外觀、連接部位和密封面���,確保沒有明顯的損壞或腐蝕。

Check the appearance, connection parts, and sealing surface of the valve to ensure that there is no obvious damage or corrosion.

清潔保養(yǎng)

Cleaning and maintenance

?�。罕3珠y門及其周圍環(huán)境的清潔����,避免灰塵和雜質(zhì)進入閥門內(nèi)部。

Keep the valve and its surrounding environment clean to prevent dust and impurities from entering the interior of the valve.

潤滑維護

Lubrication maintenance

對于帶有操作機構(gòu)的氣動高溫球閥���,定期涂抹適量的潤滑劑�����,以減少摩擦和磨損�����。

For pneumatic high-temperature ball valves with operating mechanisms, regularly apply an appropriate amount of lubricant to reduce friction and wear.

密封件檢查

Seal inspection

定期檢查閥門的密封件�����,如發(fā)現(xiàn)老化或損壞��,應及時更換�,以確保閥門的密封性能

Regularly inspect the sealing components of the valve. If aging or damage is found, they should be replaced in a timely manner to ensure the sealing performance of the valve

本文由 良工閥門 友情奉獻.更多有關(guān)的知識請點擊 http://www.353005.cn/ 真誠的態(tài)度.為您提供為全面的服務.更多有關(guān)的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from Lianggong Valve For more related knowledge, please click http://www.353005.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

企業(yè)公告:

企業(yè)公告: